Power Generation

WORK PERFORMED

- Removal of old umbilical lines & hardware

- Cleaning of the existing cable brackets

- Installation of new umbilical lines & hardware

SUMMARY

TIME

Project completed in a week

COST

Completed during a pre-scheduled outage

SAFETY

Completed without any near misses or safety incidents

CLIENT NEED

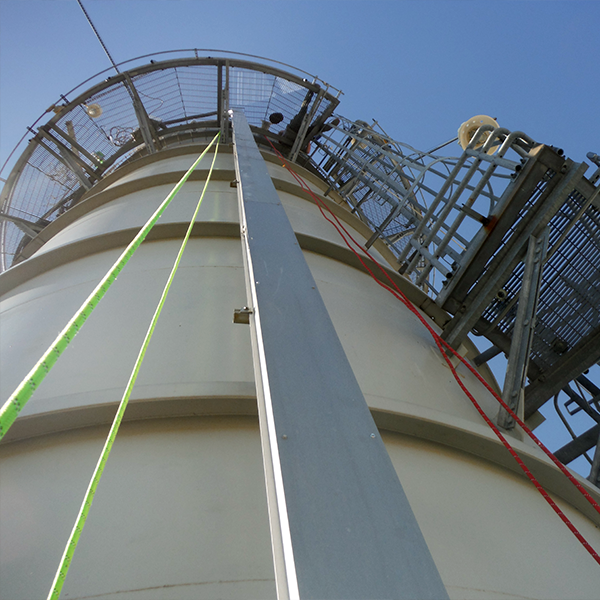

Two HRSG stacks

Accessing the umbilical line

Cable bracket cleaning in progress

ACCESS

Lifting the cable

Cable installation in progress

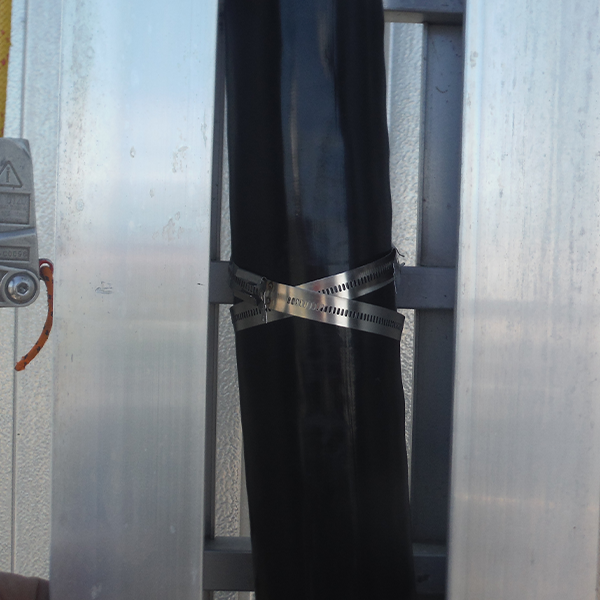

Cable secured

SOLUTION

RESULTS

For additional information about our company and services we provide, please give us a call anytime

770-255-1313