Industrial Fabrication For Ladders, Piping, Conveyors, and More

IA Mechanical offers fabrication services for plants and facilities while prioritizing quick and high-quality services for clients. IA Mechanical has a team of expert engineers who design several components needed for retrofitting mechanical equipment or custom builds. If there is a component in your facility that needs special construction to repair and make run again, IA Mechanical can fabricate their unit either at their warehouse or on-site if feasible.

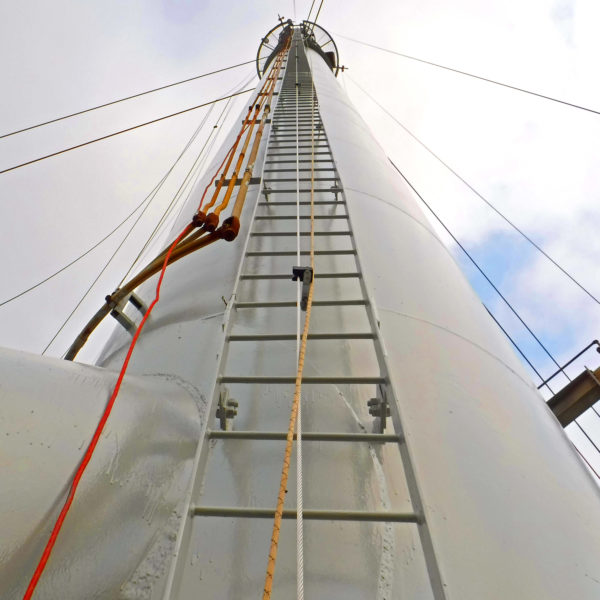

Our team will work with facilities to meet their needs regardless of the piece needed. Often, this includes pieces such as chutes, conveyors, silo liners, ladders, platforms, stairs, and piping. From there, our team fabricates the component and makes sure it works for your equipment and situation. This process is often long and requires skilled engineering processes. Below is an outline of the steps required to fabricate a new piece.

Our team will work with facilities to meet their needs regardless of the piece needed. Often, this includes pieces such as chutes, conveyors, silo liners, ladders, platforms, stairs, and piping. From there, our team fabricates the component and makes sure it works for your equipment and situation. This process is often long and requires skilled engineering processes. Below is an outline of the steps required to fabricate a new piece.

The Fabrication Process

Fabrication is the process of making metal products, such as custom-made pieces for equipment. Fabrication includes the manufacturing process from beginning to end. The main parts of the metal fabrication process are bidding, planning, and production. Typically, welding is a step in the fabrication process as well. Working aside welders and fabricators, the large team of workers consists of engineers, designers, machine setters, blacksmiths, ironworkers, and managers or supervisors. Each person on the team has a special role to work together and complete the task or project at hand.

During the bidding phase, the scope of work is determined which is an important step of the process as many important details are set. Once the bidding process is complete, it moves into the critical planning phase. This is where the designers and engineers work very closely with the client to determine critical details to ensure the plan and execution are exactly what the client needs. We dedicate a decent amount of time to discuss the process with clients to make sure their needs are met. Many people are involved in this process, especially if they play a large role in execution, such as a welder.

The last step is the production phase, in which the hands-on work takes place. Raw materials take shape and are put together to create a final product during this phase. In this step, welders and fabricators become involved as products are cut, bent, and formed. At the end of this step, a final product should be completed and then goes through a review process to ensure it meets standards and fits the piece of equipment.

The last step is the production phase, in which the hands-on work takes place. Raw materials take shape and are put together to create a final product during this phase. In this step, welders and fabricators become involved as products are cut, bent, and formed. At the end of this step, a final product should be completed and then goes through a review process to ensure it meets standards and fits the piece of equipment.

If you find your company in a position where you need a piece fabricated for your operation to run smoothly, call IA Mechanical today. We can help to fabricate many different pieces of equipment. We can also provide welding services as that often accompanies fabrication jobs. We offer many years of experience and value minimal downtime to save you money and time, but we never sacrifice the quality of service.